- Water Filters[10]

- Ice Makers[2]

- Packaging Machinery[1]

- Plastic Blowing Machinery[3]

- Water Treatment[10]

- Water Filter[2]

- Water Bottles[1]

- Beverage Processing Machinery[2]

- Water Filter Parts[10]

- Bathroom Sets[8]

- Water Softeners[8]

- Water Dispensers[9]

- Kitchen Faucets[1]

- Testing Equipment[1]

- Contact Person : Mr. Liu Frank

- Company Name : Shenzhen Ecowell Purification Company Limited

- Tel : 86-755-28432281

- Fax : 86-755-28432280

- Address : Guangdong,Shenzhen,Longgang District

- Country/Region : China

- Zip : 518117

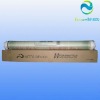

DOW FILMTEC BW30 400 RO membrane

BOW FILMTEC BW30 400 RO membrane,

Make of Membrane :DOW FILMTEC

Model: BW30 400

Origin of country: USA

DOW Filmtec BW30-400

| |||||||||||||||||||||||||||||||||||||||||

| Product Dimensions in Inches (mm) | A | B | C | |

| BW30-400 | 40.0 (1,016) | 1.125 ID (29) | 7.9 (201) |

Important Information:Proper start-up of reverse osmosis water treatment systems is essential to prepare the membranes for operating service and to prevent membrane damage due to overfeeding or hydraulic shock. Following the proper start-up sequence also helps ensure that system operating parameters conform to design specifications so that system water quality and productivity goals can be achieved. Before initiating system start-up procedures, membrane pretreatment, loading of the membrane elements, instrument calibration and other system checks should be completed.

DOW FILMTEC BW30 400 RO membrane